Optional

Features

For Blow Moulding Machines

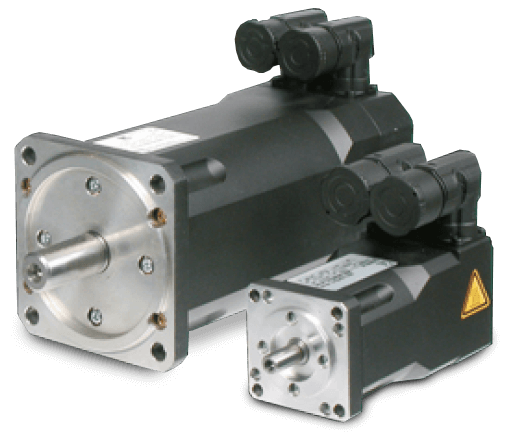

Servo System Based Gear Pump

- High Energy saving from 20% to 45%

- The synchronous permanent magnet servo motor has higher efficiency and better power factor and no slip as compared to normal AC Motor

- Due to Close loop servo system; dynamic response to flow and pressure changes is very fast and accurate. This results in improvement in the quality of the product being produced in the machine

- This servo drive has conformal coating on the Electronic card and hence better protection against dust, contamination, rust and hence longer life

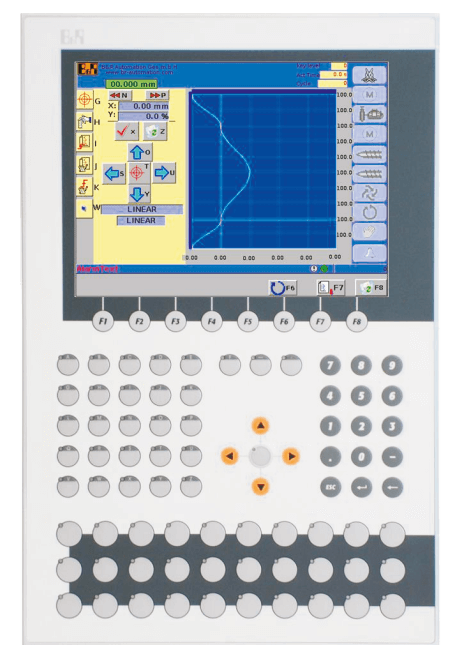

Multipoint Parison Programmer (B&R / MOOG/BECKHOFF)

- Integrated Parison control Block for precise parison control

- Upto 200 parison point profile can be set by operator.

- Parison profile curve can be stretched or compressed. Start and End point are settable,

- Real time trace for Set, Actual and control deviation can be made with settable sampling time

- Easy access for the parison profile entry with the dedicated keys.

- Numeric representation of the profile points is provided with Recipe and Alarm Management.

Robotic Gripper

- Automatic Container Ejector for Easy handling and convenient flash cutting

In-Mould Labeling

- Automatically stick the label on product surface.

- Advantage to reduce the cost of labour and avoid error of lable stick.

In addition we can also infer and align

- 01Auto Lubrication

- 02AC Control Panel

- 03Energy Meter

- 04Pre Blow Adjustment

- 05Unscrewing Unit

- 06Pre Sealing Adjustment