ibc, tanks, liquid, storage, blow, molding, machine, manufacturers, hdpe, plastic, jagmohan

The IBC Tank: An Innovative Solution for Liquid Storage

IBCs, or intermediate bulk containers, are industrial-grade containers designed for the bulk handling, transportation, and storage of liquids, semi-solids, pastes, or solids. They are also referred to as IBC tanks, IBC totes, IBCs, or pallet tanks.

IBC Tanks- A Structured Design for Smart Storage

The name "intermediate bulk container” best describes the size one may anticipate for smart storage. Although IBCs come in a variety of sizes, a typical IBC tank has a total capacity of 1,000 liters. IBC tanks are typically 1,000 x 1,200 x 1,152 mm in size.

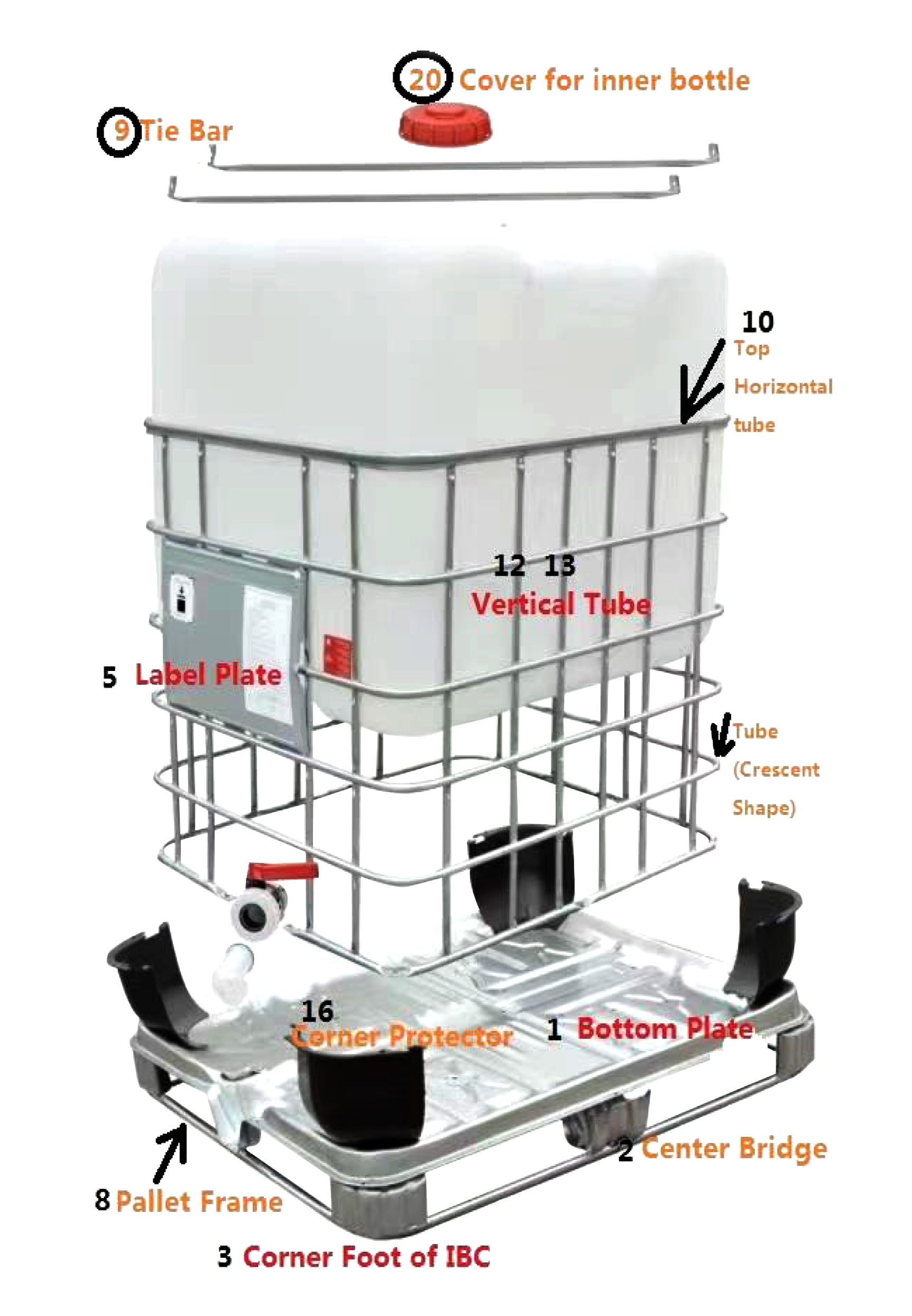

These tanks are made of high-density polyethylene (HDPE) material, which provides durability and resistance to UV rays, rust, and corrosion. IBC tanks feature a palletized base for easy forklift handling and are equipped with a top fill cap, a valve for dispensing water, and often an integrated sight gauge for monitoring the water level. It also includes inner container, outer cage, vertical plate, top opening lid and label plate.

The components are common in IBC tank designs, variations may exist depending on specific manufacturer specifications or industry requirements.

Versatility and Uses:

IBC tanks offer durability, stack-ability, reusability, and easy handling through their standardized dimensions and design. They provide a flexible solution for storage and transportation needs, ensuring the safety and integrity of the contained substances. The wide range of applications across industries like chemical, pharmaceutical, water conservation and disaster management.

Here are a few common uses:

Emergency Water Storage: In times of emergencies or natural disasters, having a reliable water supply is crucial. IBC water tanks can be quickly filled and provide a secure and hygienic storage solution for emergency water reserves.

Agriculture and Irrigation: IBC tanks are ideal for agricultural purposes, such as irrigation or livestock watering. They can be easily connected to irrigation systems, ensuring a steady supply of water to crops or animals.

Construction and Job Sites: On construction sites or remote job locations, access to water may be limited. IBC tanks can serve as temporary water storage, providing a convenient and reliable water source for various construction activities, dust suppression, or mixing concrete.

Food and Beverage Industry: IBC tanks play a crucial role in the food and beverage industry for storing and transporting liquids such as water, juices, oils, syrups, and food-grade additives. These tanks are often made of high-quality, FDA-approved materials that maintain the hygiene and quality of the products.

Waste Management: IBC tanks are employed in waste management systems for the collection, storage, and disposal of liquid waste or hazardous materials. They offer a secure and compliant solution for handling and transporting waste, reducing environmental risks.

IBC tanks offer several cost-effective advantages over traditional tanks.

Here are few benefits mentioned below

- Lower Initial Cost: IBC tanks generally have a lower upfront cost compared to traditional tanks of similar capacity. This makes them a more affordable option for individuals or businesses with budget constraints.

- Reusability: IBC tanks are designed to be reusable, allowing them to be used for multiple purposes and over an extended period. Traditional tanks, on the other hand, may require replacement or maintenance more frequently, resulting in additional costs over time.

- Durability: IBC tanks are constructed from durable materials, such as high-density polyethylene (HDPE), which are resistant to UV rays, rust, and corrosion. This durability reduces the need for frequent repairs or replacements, resulting in long-term cost savings.

- Space Efficiency: IBC tanks have a stackable design, allowing for efficient use of storage space. When not in use, they can be stacked on top of each other, reducing the footprint required for storage. This is particularly beneficial for businesses or individuals with limited storage space.

- Easy Transportation: IBC tanks are designed with features like palletized bases and forklift pockets, making them easy to transport and relocate. This eliminates the need for specialized equipment or additional costs associated with transportation.

- Versatility: IBC tanks can be used for various applications beyond water storage, such as storing and transporting other liquids. Their versatility adds value by maximizing their utilization for different purposes, reducing the need for separate tanks for different substances.

- Reduced Installation Costs: Traditional tanks often require professional installation, which can be costly. IBC tanks, on the other hand, are relatively easy to install without the need for specialized expertise. This eliminates the expense of hiring professionals for installation.

- Maintenance Savings: IBC tanks typically require minimal maintenance. The durable materials they are made of, combined with their design features, reduce the likelihood of leaks, cracks, or other issues. This results in lower maintenance costs over time compared to traditional tanks that may require regular inspection, cleaning, or repairs.

IBC (Intermediate Bulk Container) tanks are witnessing a rapid surge in acceptance and adoption across India. These innovative and versatile liquid storage solutions have become increasingly popular among industries and businesses due to their numerous advantages. JAGMOHAN takes pride in providing machines with advanced technology to manufacture IBC tanks. With 43 years of distinction and spanning over 63 countries, JAGMOHAN offers quality and reliability to its customers. Redefining polymers to plastic products, JAGMOHAN is empowering the Blow Moulding technology in every parameter.