Injection, Blow, Moulding, Triple Layer, automobile, plastic storage, industries, manufacture products

Injection Blow Molding - What’s it about?

From agriculture to automobile, you may notice plastic storage requirements in various sectors. But ever wondered how these containers are produced? A process known as blow moulding is utilized by industries to manufacture products of specific dimensions and for particular applications.

Blow moulding can create different products of varied shapes, having hollow applications.

Some examples of such applications are:

- Pharma Containers

- Water Storage tanks & Industrial Bulk Containers

- Plastic drums for Domestic as well as Industrial Purposes

- FMCG rigid packaging

- Lube Oil and Edible Oil Cans

- Gardening Watering Cans

- Pesticide Knapsack Sprayers

- Milk containers

- Household Planters

- Aero Floats, Solar Floats and Pontoon Floats

- Automobile Fuel Tanks, Air Vents, Bellows & Spoilers

- Road Safety Equipment like Road Barriers, Cones, etc.

- Toys & Playschool Equipment

-

& many more....

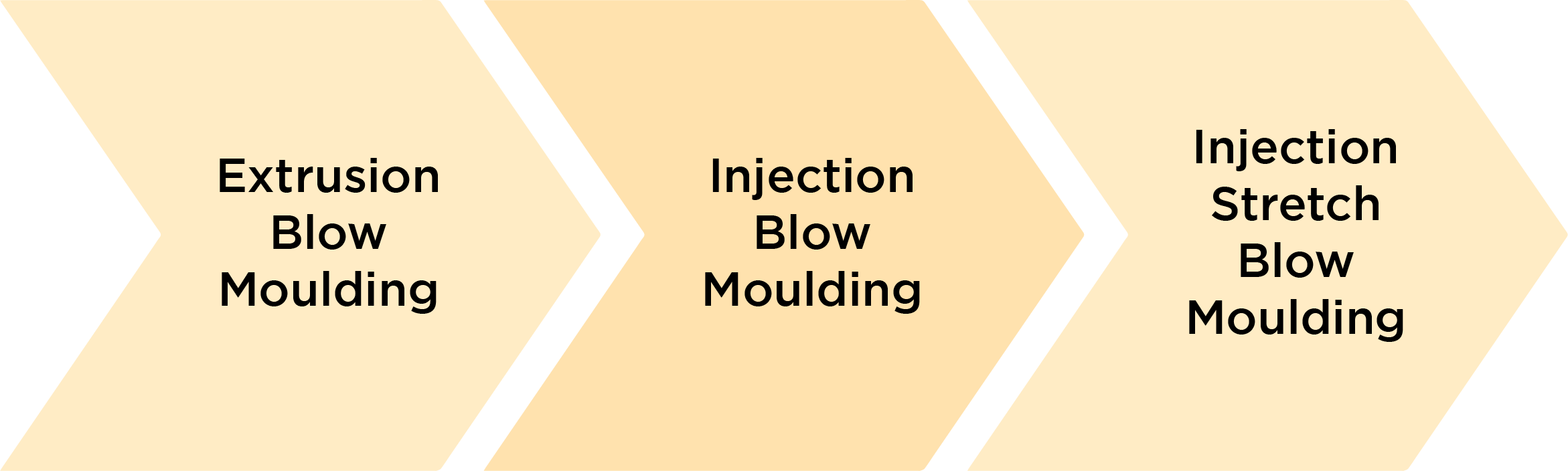

There are 3 types of blow moulding processes –

Today, let’s talk about the Injection blow moulding process (IBM).

In IBM, the raw material or preform is injection-moulded to form a hollow core pin or mandrel, followed by passing into a second process station while the preform is still hot. Then, the injection mould opens, and the preform goes through rotation. The preform is given a particular shape corresponding to the blow mould form through blowing process in virtue of compressed air.

Injection blow moulding comprises three phases: Injection, Blowing and Ejection.

- Injection

The IBM machine consists of an injection barrel and screw assembly that melts the polymer, which is then fed into a manifold. Here it gets injected via nozzles into a heated and hollow preform mould. It becomes the external shape that gets clamped around a core rod governing the internal shape of the preform. The preform comprises a fully-formed bottle neck having a thick tube of polymer forming the body.- Blowing

As the preform mould opens in this step, the core rod is rotated and attached to the hollow, chilled blow mould. The core rod allows the entry of compressed air into the preform, thereby inflating it to the shape of the finished article.- Ejection

The ejection phase of IBM, as the name sounds, rotates the core rod to an ejection position. Once the product is finished, it is stripped off from the core and tested for leakage before packing.

An injection blow moulding machine consists of an integral injection unit and a multi-impression mould assembly where the mould cores are mounted. The neck form is completely moulded in the injection stage with the highest precision. Three sets of core rods allow concurrent preform injection, blow moulding and ejection.

What makes Our Blow Moulding Machines unique

Jagmohan PlaMach Pvt. Ltd. is an ISO 9001:2015 certified company, one of the pioneers in blow moulding since 1980 for customers in India and worldwide. We have the largest manufacturing plant which gives us an advantage. In total, we have our presence in 63 countries, 5000+ global machine installations,over 600 clients , and a team of 230+ people. Our IBM machines come with a feature of automation, having capacities ranging from 5ml-1000 ml.

Each of our injection blow moulding machines goes through a well-regulated quality control process to ensure robustness, reliability, and simple yet sturdy assembling for low-cost maintenance. We specialize in delivering customized solutions and applications. Continuous R&D and machine upgradation as per advanced technology remain our commitment.

Features

- Full Servo Machine, both Hydraulics + Rotation Table functions are controlled by Servo Motors ensuring very low power consumption.

- Our unique machine design of Hydraulics under the Rotation Table making our machine perfect for pharma applications.

- Less machine height allows easy operation & handling.

- Product convey or with counter feature connected to PLC giving instant production data always available handy.

Our high-tech blow moulding machines shape polymers to perfection.

Jagmohan PlaMach Pvt. Ltd. is one of the leading IBM manufacturers in India and its machineries deliver various applications that are repeatable and durable. Our awards and achievements include Lifetime Achievement by The Economic Times and the Modern Plastic Award for the Largest Extrusion Blow Moulding Manufacturer, presented by Mobil. We simplify the manufacturing of blow moulded products with advanced machinery and equipment.